Whether you’re opening a new restaurant, or just revamping your current one, you’re going to need to install some form of FOG mitigation system. FOGs—or fats, oil and grease—are natural by-products produced during cooking. But if they’re washed down the sink they can congeal and form monster fatbergs which can block whole sewer networks.

Because of the devastating environmental impact, this can cause, not to mention the extreme expense of simply clearing the blockage and repairing the damage, water companies can fine businesses who haven’t taken the necessary precautions to stop FOG being flushed down their drains.

Grease Trap or Grease Interceptor – Do You Know the Difference?

Fortunately, grease management solutions are readily available. You’ve probably already heard of grease traps and grease interceptors, but what’s the difference, how do they work, and which is right for your business?

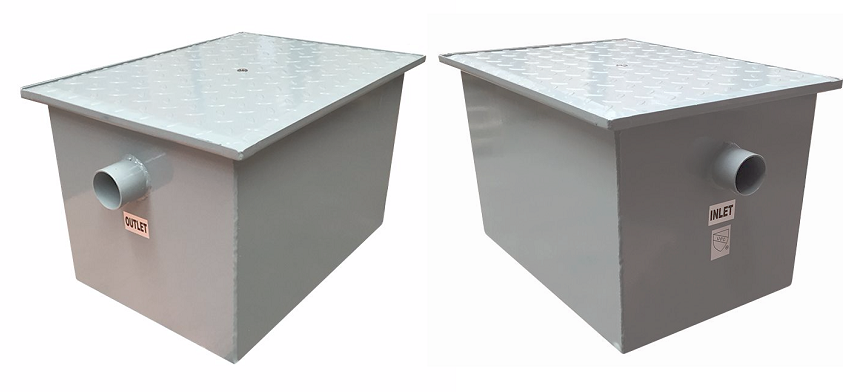

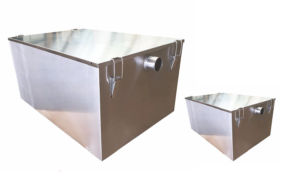

Grease traps, either passive stainless steel grease traps or automatic grease traps (or GRU's), are often the first-choice FOG management solution for most kitchen operators. They’ve been around since the 1880s and in principle, the technology hasn’t changed much since then. Basically, a grease trap is a receptacle which wastewater flows through before entering the drainage system. It is designed to “trap” the FOG from the wastewater, allowing only clear water to escape.

They work on the basis that FOG is 10 to 15% less dense than water and that the two can’t mix. When wastewater enters the trap its flow rate is reduced so that it can cool and separate into three distinct layers. The FOG rises to the top because it’s the least dense and it’s trapped using a series of baffles. Food debris is the densest layer, so it settles at the bottom of the tank, allowing the now clear wastewater to escape through an outlet.

Grease interceptors work in largely the same way, which is why, frustratingly, the two terms are often used interchangeably. But there are significant differences between the two.

Flow Rate

The main difference between a grease trap and a grease interceptor is the flow rate of wastewater they can handle. Grease traps work best with a lower volume of flow—ideally less than 50 gallons per minute. Generally, this covers most foodservice businesses.

But large-scale establishments with a much higher volume of flow will need to install a grease interceptor. They are designed to operate in high-pressure water environments and can handle extensive grease flows.

Size

Grease traps are normally the size of a bread box or a mini-fridge. Although sizing can vary quite dramatically, from anywhere between 10 gallons to 500 gallons. They can be installed inside the kitchen, usually beneath the sink.

Grease interceptors, with their larger holding capacity, are much larger and typically have a holding capacity of over 500 gallons. Due to their size, they can’t be neatly fitted under the kitchen sink and are instead often installed outside an establishment underground. They work best if they are located near the fixture they serve. However, they can often give off a bad smell so they should be placed far away from any areas that customers frequent.

Maintenance

Grease traps require cleaning more frequently than grease interceptors. That’s because they tend to be smaller sized units which get filled up much more quickly. Ideally, grease traps should be cleaned either monthly by a specialist or daily by your employees.

As the capacity of grease interceptors is greater, they can gather a larger amount of FOG over a longer period of time. Therefore, they need cleaning less often. Good practice dictates that grease interceptors should be emptied and cleaned at least once every three months. But while grease traps can be cleaned by hand, grease interceptors must be serviced by specialists. Technicians use a large hose to pumps the FOG from the interceptor into a truck equipped with a holding tank.

The 1/4 Rule

Although this is generally a good rule of thumb for any cleaning schedule, for more accurate measure businesses that have a grease trap or grease interceptor should use the ¼ rule. The ¼ rule is an internationally recognised standard which provides a good estimate on when to clean on out the grease trap or interceptor.

It states that once ¼ of the trap has been filled with FOG it should be pumped out. This rule applies regardless of whether a month or three months have passed. That’s because as soon as that much FOG has been trapped, the device no longer operates as effectively and there is an increased risk of blockages and overflows. If over time you notice that your trap or interceptor regularly reaches that ¼ mark in a couple of weeks, consider sizing up.

It’s also important to note that the frequency of required cleaning can vary depending on the amount of grease produced in the kitchen. For instance, fast-food restaurants produce much more FOG than a predominantly vegetarian restaurant and will, therefore, have to clean their equipment more regularly.

Whatever your business needs, grease trap or grease interceptor, it’s vital to invest in the right grease management solution. Choosing the perfect fatberg-busting box can dramatically reduce the environmental impact that your wastewater can potentially have on public drainage systems and public watercourses in general.

Leave a Comment

Your email address will not be published. Required fields are marked *