Grease traps - a topic only recently emerging into the public consciousness following widespread publicity surrounding the discovery of huge fatbergs; the scourge of the sewers. Found lurking in the depths below our feet, fuelled by changing lifestyles and diets, these monsters have become prevalent in many cities worldwide. But where did grease traps originate and how have they developed through the years?

Grease Trap Debut

Surprisingly not a contemporary topic, grease traps are, in fact, a part of environmental history… albeit not a well-known part. Emerging under many guises, grease traps, grease interceptors, grease recovery units, they all have a sole purpose – to prevent fats, oil and grease (affectionately known as FOG for short) from entering the worlds sewer systems.

Enter Nathanial Whiting, an American visionary that patented the first rudimentary grease trap in the late 19th Century. Although basic and crude in design, this original patent is what all modern systems derive from.

The first documentation for the use of grease traps was in the Victorian period when the sewer system was invented and put into action. This fact clearly shows that the negative impact that FOG has on sewers was evident even then. Although use was sporadic and not obligatory, the roots of the war against grease had taken hold, roots that have continued to grow and broaden over the last 100 years.

Basic Design

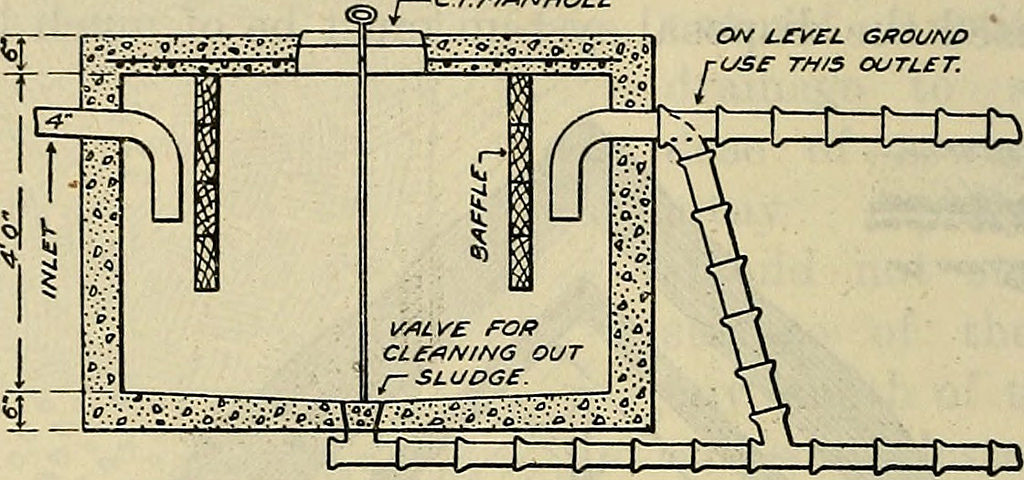

The basic design of modern day grease traps is remarkably similar to the original Victorian edition. Basically, a box positioned between the source of grease and the wastewater outlet, FOG is prevented from passing any further, trapped until cleaned out, treated and responsibly disposed of. Over the years, as materials, manufacturing processes and general understanding have progressed the basic principle has evolved to become more efficient in design and use. Now constructed using a range of materials such as stainless steel, epoxy coated steel and even plastic, today’s grease traps can be positioned inside, outside, above or below ground to accommodate the differing needs of every business. While passive grease traps (also referred to as manual or gravity operated) are the standard addition to foodservice operations presently, the more effective Automatic Grease Traps (or Grease Recovery Unit, GRU) are rapidly growing in popularity.

Bringing Grease Traps Up to Date

The boom in the growth of the foodservice and catering industry coupled with changing diets and cooking techniques greatly contributed to increasing fatberg concerns. As more commercial kitchen waste was being disposed of directly into sinks and drains, without any form of protection against nasty build-ups, it became evident that something needed to be done. Between 1990 and 1991 legislation was drawn up and enforced stipulating strict guidelines in reference to the disposal of kitchen waste, especially in commercial premises. All commercial businesses that prepare and distribute food are now required to install and regularly maintain appropriate grease traps with correct, up-to-date documentation available to substantiate procedures. With water authorities clamping down on irresponsible practices, grease traps have never been more in the limelight.

For more information about how grease traps can protect the future of your business, give us a call on 01455 815214 or start a conversation with us in the live chat.

Leave a Comment

Your email address will not be published. Required fields are marked *