Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

Last Updated: 6th Nov 2023

Grease Traps & How They Work

What is a grease trap and what do they do?

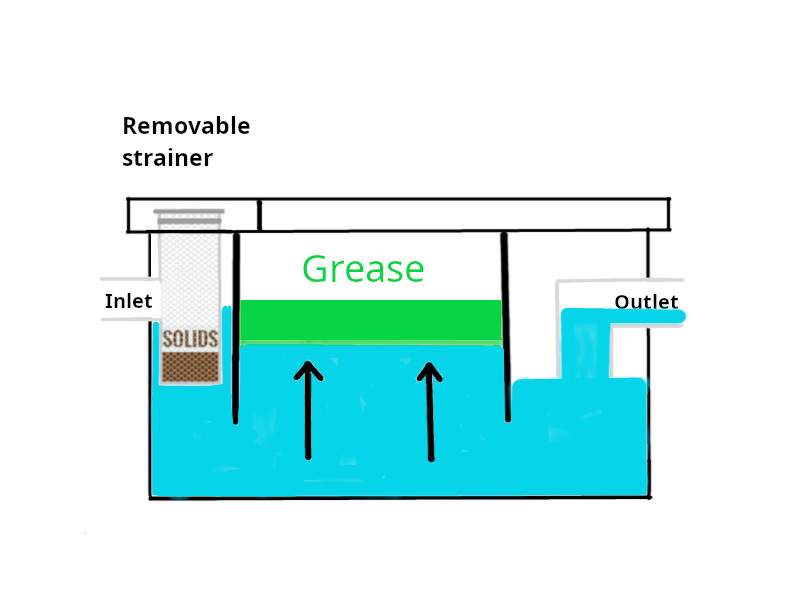

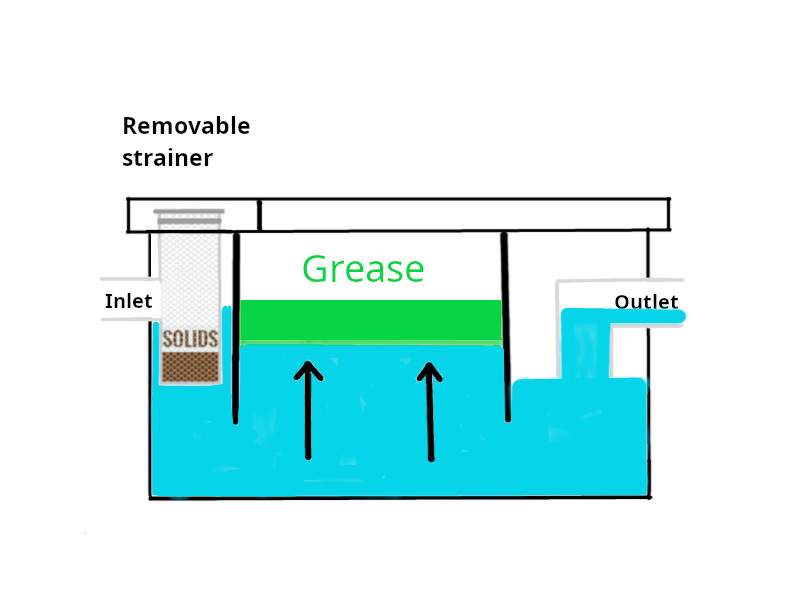

In the simplest possible form, a grease trap is a box with an inlet and outlet which attach to sink pipes and the main drain. They are available in a choice of sizes and capacities to meet the demands of all businesses. A secure lid allows traps to be easily cleaned when necessary. Grease traps, sometimes known as separators or interceptors; prevent fats, oils and grease produced by commercial kitchens from entering the drainage system and causing blockages. They act as a filter between sinks and the main sewer system.

How do grease traps work?

When waste is poured down the sink it runs into the grease trap. Any solid matter sinks to the bottom, the water remains in the middle and any lighter FOG floats on the top. Only the filtered wastewater flows into the drainage system.

All food solids and FOG are contained in the tank, increasing in volume daily as more waste is put down the sink. Grease traps can be cleaned out in-house however most businesses opt to use qualified engineers. All fats, oils and greases should be disposed of by licensed carriers

It is vital that businesses take responsibility with regard to the correct disposal of all FOG products. The issue of large fat bergs in drainage systems, created from build-ups of fat and grease, have begun to impact not only the free-flowing of wastewater but also the environment. For this reason, authorities are now tracing formations back to the source. If the business has no measures in place to prevent FOG products from entering drains, such as suitable grease traps, they will be on the receiving end of a hefty cleaning bill and maybe even a fine and prosecution.

How do I choose the right grease trap?

You will need to firstly ascertain the flow rate of your sink and how much waste is typically disposed of. All grease traps should specify the flow rate; if you are unsure it is always best to go with a slightly larger option to guarantee that the unit can handle demand.

Capacity will also play a major role in selecting the right grease trap. All units should show a grease capacity in kilograms and a total capacity to the inlet / outlet in litres.

Your next decision is positioning. Do you need a unit for indoor, outdoor or underground use? This will depend on the size of your business and the number of sinks you wish to run into one trap. It may also dictate the construction materials used for your grease trap. Average sized operations generally opt for indoor situation, typically being housed under the sink, while underground alternatives are better suited to larger premises.