A Brief Introduction to Grease Traps…Getting up to Speed

Grease trap noun – def. ‘: a trap in a drain or waste pipe to prevent grease from passing into a sewer system’ Source: Merriam-Webster.com

Having recently become somewhat of a buzz word in the commercial foodservice industry and often associated with the terms fatberg and FOG (fats, oil and grease), grease traps are not a new thing. Surprisingly, the idea of a grease trap specifically designed to prevent fats, oils and grease from entering the sewer system, has been around since the Victorian era (late 19th Century) where it seems that troublesome drain blockages also appear to have caused issues. These first primitive boxes are what all grease traps today are based on.

Important Legislation

UK Water Industry Act 1991 section 111

“…no person shall throw, empty…into any public sewer or into any drain…communicating with a public sewer, any matter likely to injure the sewer or drain, to interfere with the free flow of its contents…” Source: https://www.legislation.gov.uk/ukpga/1991/56/section/111

All businesses must work within the law. Installing an appropriate grease trap is essential to ensuring every commercial kitchen complies with regulations.

How Do Grease Traps Work?

The primary feature of a grease trap is to prevent any untoward kitchen matter (anything other than water) from entering the sewer system; this includes FOGS and food debris etc.

There are different types of grease traps for commercial kitchens on the market, often being broadly broken down into two main sections - passive/manual traps or automatic separators/GRUs (grease recovery units). Whether attached to sinks, ovens, warewashers or elsewhere in the kitchen where FOG is produced, grease traps will perform the same basic function, all be it with slightly differing approaches.

The size of grease interceptor required will depend on the flow rate of fluid through the kitchen either through sinks, warewashers or equipment; low flow rate = smaller trap, high flow rate = larger trap. With a full range of sizes on offer to suit every flow rate, the basic design works in the same way whatever the dimensions.

Manual Grease Traps

Typically a durable stainless steel or epoxy coated steel box designed to trap grease until cleaned out.

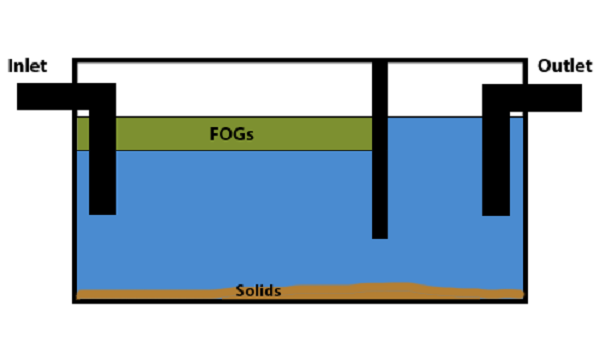

- Waste water or effluent enters the grease trap and fills the tank

- A system of baffles may be used to slow down water and allow FOGs to cool and effectively separate

- Solids settle/sink. Some models may have a strainer to catch solids, reducing quantity settling in the bottom of the trap

- FOG floats (being lighter than water)

- Outlet syphons water through to the drainage system

FOGS and solids sit in the trap until emptied and cleaned (a task advised when the box is approximately 25% full). The stagnant waste can often lead to bad smells, increased risk of pest infestation and risk of unsanitary kitchens…not ideal. Passive grease trap cleaning, whether carried out manually or with a pump, isn’t an appealing task and it’s always advised to allow professionals to do the job (although this will lead to ongoing operational costs). Be aware that if passive grease interceptors are neglected for too long they will become ineffective as the tank fills with FOG.

Passive grease traps can be positioned above ground, typically where the source of FOG is or underground in an external location. Whether opting for a small indoor or large outdoor model, traps will function in the same way.

Did you know? In kitchens where FOG production is high, it may be beneficial to double up on grease management systems. While traps will remove a hefty amount of FOG from waste water, they aren’t 100% foolproof. To maximise effectiveness and minimise FOG ending up in the sewer, two traps can be placed side by side; any unsavoury elements escaping the first trap will be caught by the next. It’s always recommended to have a site survey carried out by an expert; they’ll let you know what you need and make sure grease management solutions are as effective as possible.

Dosing Systems

Dosing systems are sometimes used in conjunction with passive grease traps. Consisting of biological treatments made-up of enzymes and bacteria, the solution is introduced to the system prior to effluent entering the grease trap. Helping to break down FOG, dosing systems and dosing pumps are not a standalone grease-busting solution, instead designed to enhance function of the basic trap.

Automatic Grease Traps

Automatic grease separators are often considered a more sophisticated grease removal system, solids and grease being separated from grey water into collection containers ready for daily disposal.

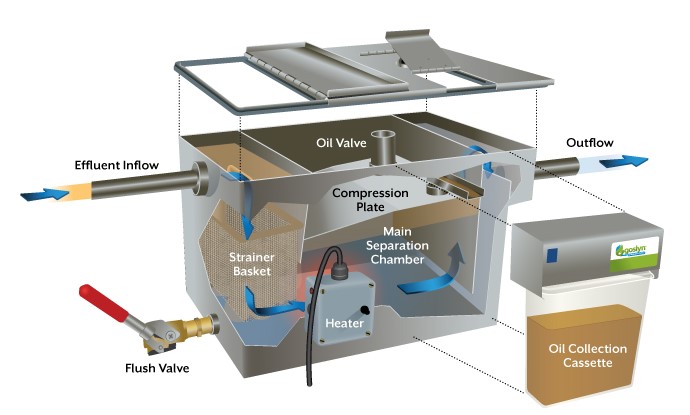

- Waste water enters the grease trap

- Passes through a filter that collects solids

- Water mixed with FOG flows through to main chamber

- Non-mechanical GRUs such as Goslyn units will have a small heater to prevent FOG from cooling and solidifying; utilising hydro-static pressure to force FOG out into external oil container. Mechanical models allow FOG to cool and separate to the surface (as with passive) however regularly skim the top layer into a separate collection container

- Water continues the journey into the sewer via the outlet, unaccompanied by any unwanted additions

FOGs and solids are effectively separated into independent containers and can be easily disposed of by members of staff without needing to shut down the kitchen and experience enforced down time. A major benefit of automatic grease separators is that they continuously remove FOGs to maintain the ongoing efficiency of the trap.

The fatberg problem is an issue at a domestic and commercial level however commercial foodservice premises will often produce considerably more offending material, with takeaways typically being the biggest contributors. Often the escape of fatberg ingredients from commercial kitchens isn’t intentional; businesses are just unaware of how working practices are creating a problem. The education of businesses and staff (and effective grease management solutions) is key to combating the rise of the fatberg once and for all. Make sure your kitchen is prepared.

Leave a Comment

Your email address will not be published. Required fields are marked *